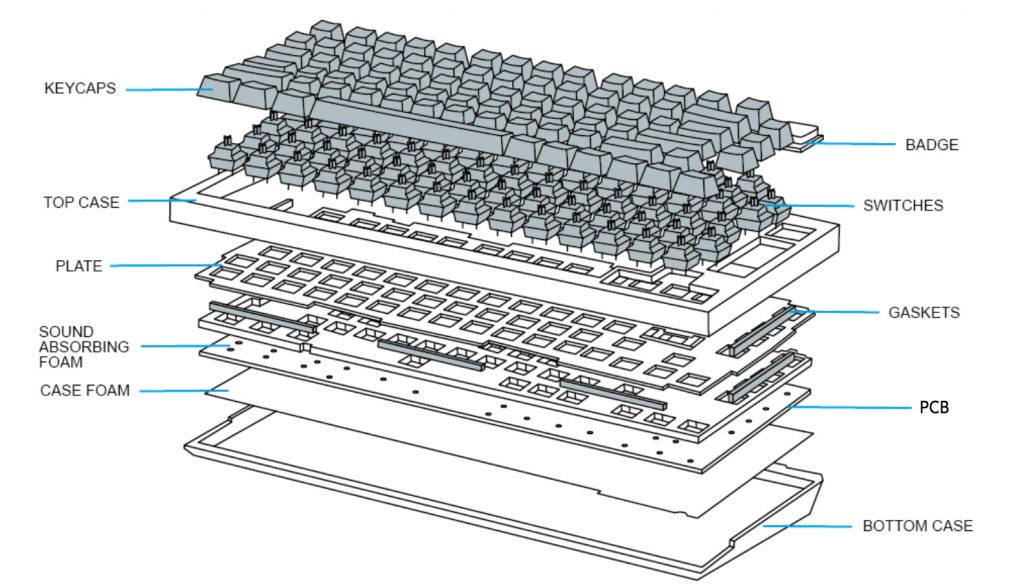

The different parts of a keyboard work together to convert keystrokes into electrical signals and send them to a computer. Each part has a critical function and can significantly impact keyboard performance, comfort, and aesthetics. This guide explains all the parts of a keyboard, including what they do, common options, and how they affect the keyboarding experience for writers, gamers, programmers, and business professionals.

Parts of a Keyboard: At a Glance

This table lists parts of a computer keyboard and their functions. Scroll down for more detailed explanations.

| Keyboard Part | Function |

| Keycaps | Visible keys that activate underlying switches |

| Switches | Transfer keystrokes to Printed Circuit Board (PCB) |

| Case | Holds everything together and protects internal components. It can be made up of a top case that sits below the switches, or only have a bottom case. |

| Gaskets | Protect internal components from dust and liquids |

| Plate | Aligns and stabilizes switches |

| Printed Circuit Board (PCB) | Converts keystrokes into electrical signals and sends them to a computer. Some have diodes for RGB backlighting |

| Stabilizers | Keep large keys stable while typing (spacebar, shift, enter, delete) |

| Power Cable | Plugs into the computer with a USB connection |

Optional keyboard parts that might not be on all keyboards include:

| Keyboard Part | Function |

| Keyboard Feet | Gives the keyboard an angle, some Das Keyboard models use a removable footbar that is also a ruler |

| Volume Wheel or Knob | Controls the volume on a computer |

| Media Keys | Keys like play/pause, previous track, next track |

| LED Indicator Lights | Usually used to indicate when caps lock, num lock, or scroll lock is activated. |

| Sound-Absorbing Foam | Absorbs sound and minimizes noise |

| O-Rings | Dampens noise and tactile feedback on mechanical keyboards |

| Sleep button | Puts the computer to sleep instantly (exclusively on Das Keyboard models) |

| USB Passthrough/s | Allows for plugging in external devices to charge, or transfer files |

Parts of a Keyboard: In Detail

The following parts make up most mechanical keyboards. The quality and style of each part can vary significantly between brands and manufacturing processes, so it’s essential to understand the different options before building or buying a pre-built keyboard.

Keycaps

Keycaps are the part of the keyboard that sits on top of the mechanical switches and that you press with your fingers. When you push on a keycap, it pushes down the switch and activates the keystroke. Both the keycaps and the switches are above the top plate, which has holes for the switches to attach to the plate and PCB. Most keycaps are made from either Polybutylene Terephthalate (PBT) or Acrylonitrile Butadiene Styrene (ABS), but keycaps can be made of virtually any material, such as resin, wood, metals like aluminum, stainless steel, or even gold! PBT keycaps are a popular choice because they are strong and durable, resist fading, and tend to have a matte, grainy feel. They’re generally more expensive than ABS keycaps, which are flexible, impact-resistant, and boast sharp colors and crisp legends. The large cost difference between PBT and ABS has led to ABS keycaps being the most common keycap material used in the market today. They cost a fraction of what ABS keycaps cost, which is why they are also on most mass-produced keyboards today.

PBT and ABS keycaps can be single shot or double shot:

- Single Shot Keycaps: Made from one layer of plastic.

- Double Shot Keycaps: Two layers of plastic molded together. One plastic comprises the main housing. The other is injected inside the keycap to form the stem and legend.

Some keycaps are dye-sublimated (also known as just dye-sub), which means their legends use digital printing technology to print the legend on the keycap. Dye-sublimated keycaps can fade over time, but laser-etched or double shot keycaps won’t fade. Laser-etched keycaps are cut into the keycap so can’t fade, and double shot keycaps are a second layer of plastic in a different color for the inscription, so won’t rub off. Double shot keycaps are usually a better quality keycap because more material is used so they’re stronger and heavier.

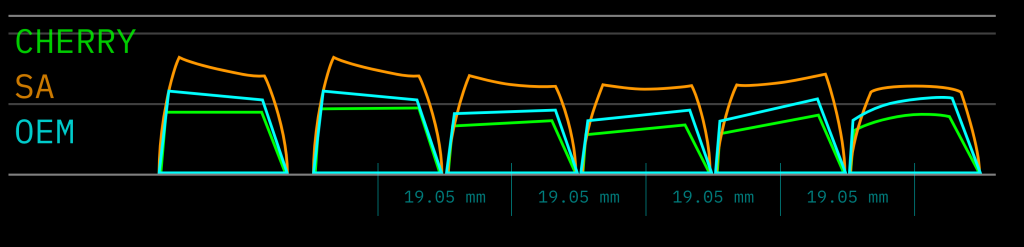

Keycaps come in many different profiles, distinguished by the following features:

- Height (high, medium, or low)

- Shape (angled or concave)

- Row Shape (sculpted or uniform)

Below are three of the most popular keycap profiles found on the market today, Cherry, SA (spherical all), and OEM (original equipment manufacturer).

Keycap profiles are largely a matter of personal preference, though they can affect performance. For example, SA profile keycaps are tall and not optimized for speed, while Cherry profile keycaps are popular among Esports gamers and writers for their balance of comfort, accuracy, and speed.

Mechanical Switches

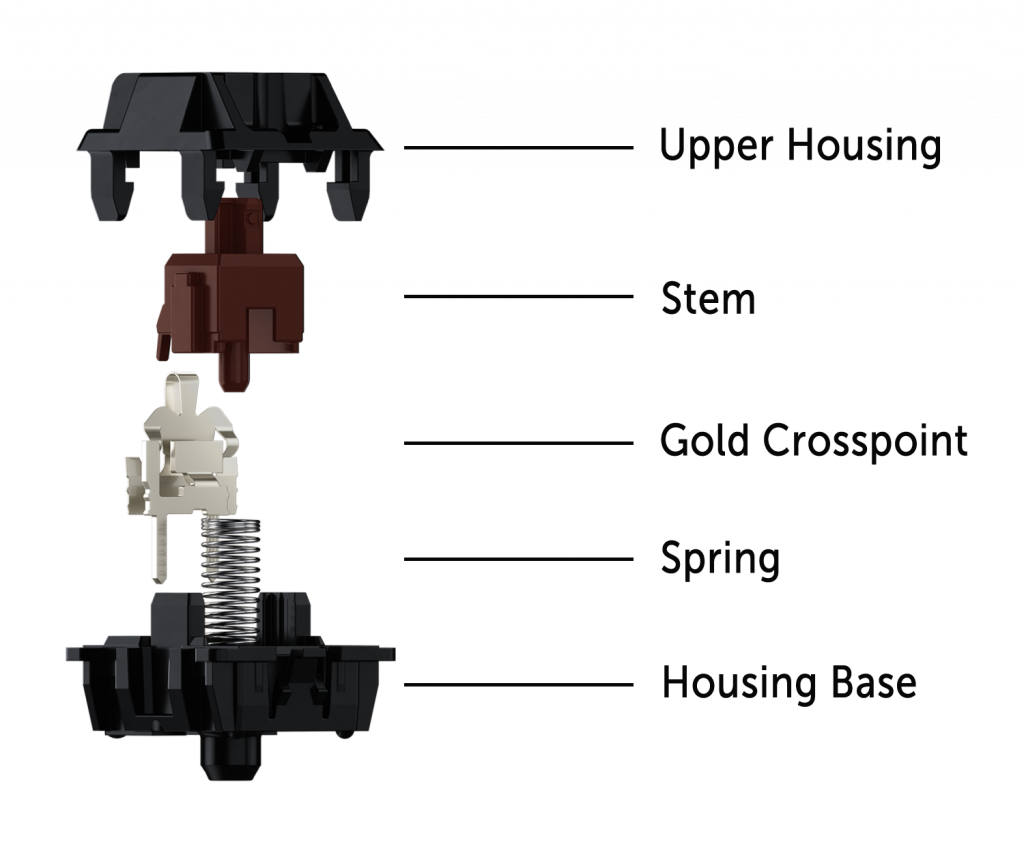

Keyboard switches are perhaps the most important parts of a keyboard because they determine the sound and feel of the keyboard while typing (in addition to the feel of the keycaps). They’re responsible for transferring keystrokes to the PCB (Printed Circuit Board) through the crosspoint (also known as the contact). Keyboard switches have several characteristics, such as the force needed to press or depress the key, the feel (tactile or linear), the sound they make while typing, the amount of travel, if they are unlit, backlit, or RGB switches, and more. Switches come in many different styles, but in general, they’re comprised of:

- Upper Housing: The top of the switch that the keycap rests on

- Stem: When pressed, the keycap travels partway down the stem and activates the contact

- Contact or Crosspoint: When activated, the contact closes the circuit on the PCB, which sends the signal to the computer

- Spring: The spring provides resistance and returns the keycap to its original position

- Housing Base: Mounts the switch to the PCB or the keyboard plate

- LED Pipe: Backlit keyboards have a single color LED light that inserts into the switch

Scissor switches and butterfly switches work differently. Typically found on low-profile keyboards, these switches feature two cross arms held together by a spring. When depressed, the cross arms fold down and allow the contact to activate the PCB.

Keyboard switches come in three different actuation types, and each offers a unique typing experience:

- Clicky: Tactile feedback with an audible click sound

- Tactile: Tactile feedback with a dampened click

- Linear: Smooth, quieter keystroke that can be silent

Switches are also differentiated by:

- Resistance: The force required to depress each key

- Pre-travel distance: The distance the key travels before it registers the keystroke

- Total travel distance: How far the key travels before it bottoms out on the keyboard

- Actuation rating: Total lifespan in keystrokes

- Mount: Some switches are designed to mount to keyboard plates, while others mount directly on the PCB

Note that some keyboards don’t have mechanical switches. Instead, they have single-sheet membranes with raised, printed “keys” that activate the circuit board when pressed. Other keyboards use rubber domes in place of switches. Membrane and rubber dome keyboards tend to be low-end, economy models with no tactile feedback, often found on laptops but not mechanical keyboards.

There are dozens of brands of switches on the market, with the most popular being Cherry MX, Gateron, Kailh, Drop, Topre, Romer-G, and Topre. Each brand makes many variations of tactile and linear switches, so the options can be overwhelming. While it’s always a good idea to try out several switches before you buy a keyboard, Cherry MX Brown switches have been the most popular switches on the market for years. They have a quiet click, tactile feel, and are rated for more than 100 million actuations.

Keyboard Case

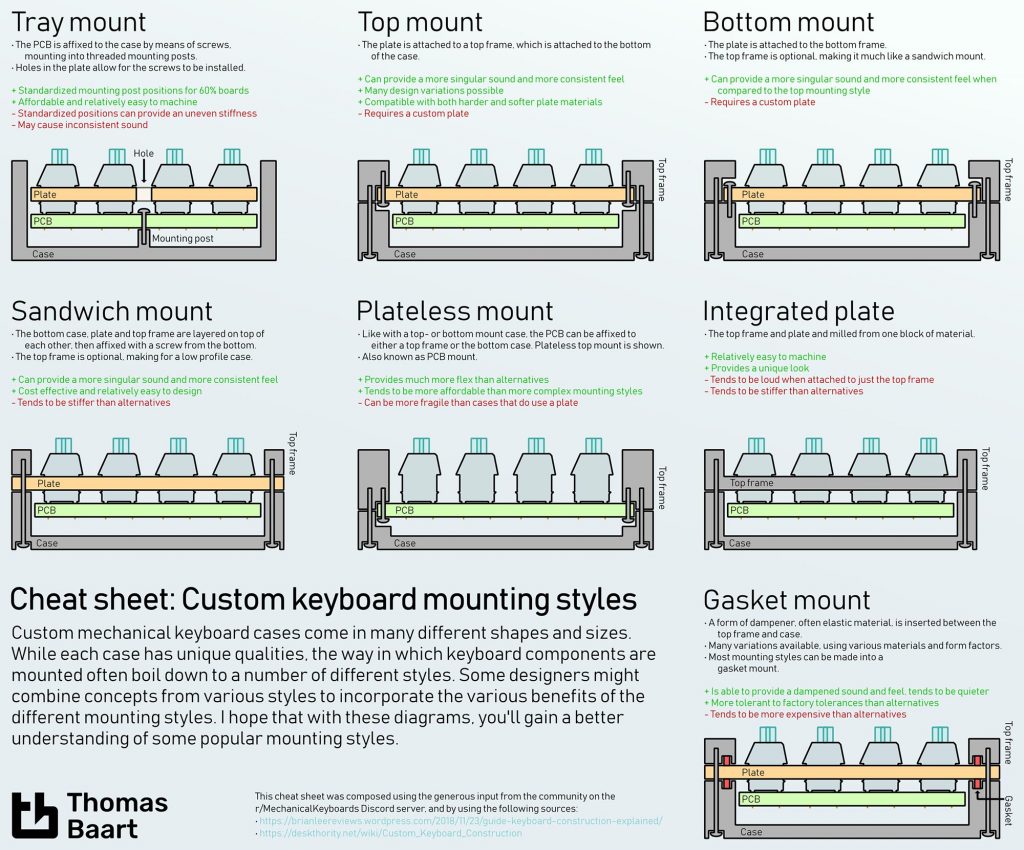

A keyboard’s case can be made up of a top case, and a bottom case. The bottom case is also sometimes called the bottom housing and houses the keyboard, while the top encloses the top of the keyboard. Not all keyboards have a top case, depending on the design and mounting style. Most keyboard cases are made from ABS plastic, but some are made from aluminum, brass, carbon fiber, and even wood. There are several different types of case mounting styles:

- Gasket Mount: Gaskets inserted between the plate and top and bottom cases dampen sound and keep dust out.

- Tray Mount: The case features mounting posts to screw the circuit board on.

- Top-Mount: The plate attaches to the top frame.

- Bottom Mount: The plate attaches to the top of the keyboard case.

- Plateless Mount: The case is designed for a keyboard that doesn’t use a plate between the switches and PCB.

- Sandwich Mount: The plate is “sandwiched” between the top and bottom case, keeping it in place.

- Integrated Mount: The top case doubles as the plate.

The case houses the keyboard’s electronics and other parts, such as the top plate and PCB, which are designed for a specific size and layout. For example, some keyboards are full-sized, while tenkeyless keyboards omit the numerical keypad, and 65% keyboards omit both the numerical keypad and function keys.

Gaskets

Gaskets help protect internal components from dirt, dust, water, and other liquids. They typically lay on the plate between the top and bottom case. Not every keyboard uses gaskets, which are usually made from rubber, but those that do can resist minor spills.

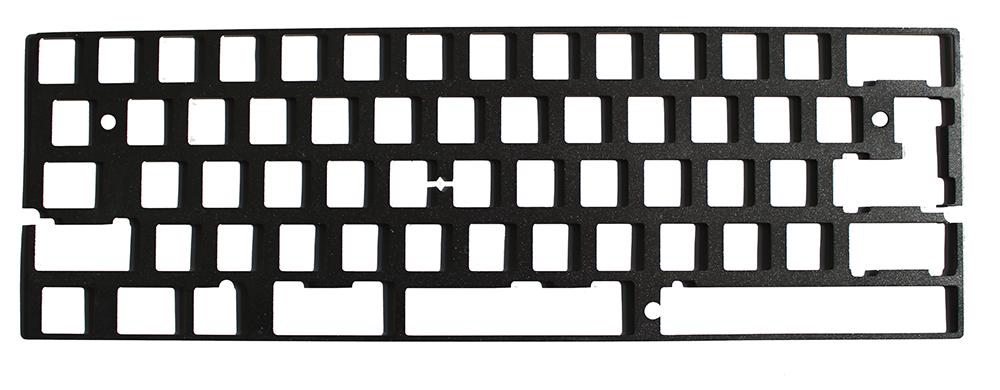

Plate

The top plate aligns and supports the switches, providing solid contact with the PCB. The switches usually clip into the plate, then the switches are soldered into the PCB. Plates have a stabilizing effect for consistency and accuracy with each keystroke, and they protect the circuit board from damage and debris that could fall between the keys. Some keyboards do not have plates, making them more susceptible to key wobble. Plates are typically made from materials such as plastic and aluminum, but brass, steel, and carbon fiber versions are also available.

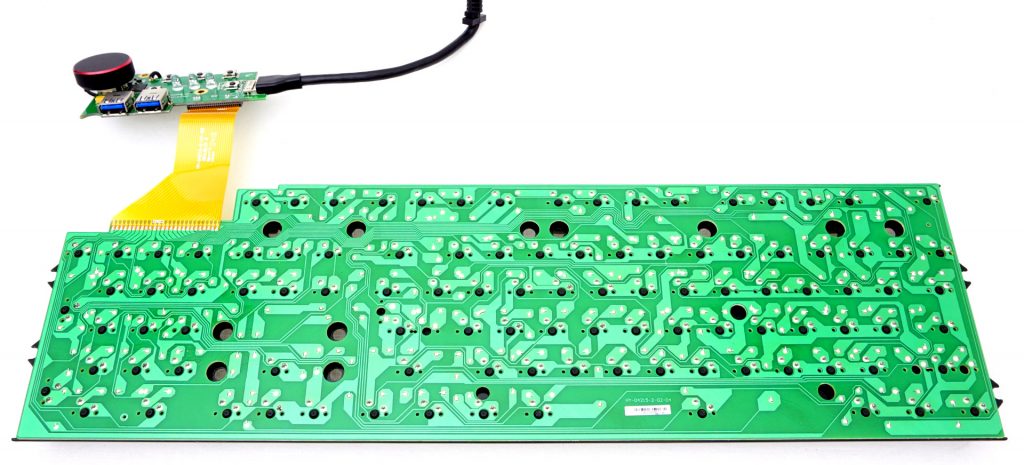

Printed Circuit Board (PCB)

The PCB is essentially the brain of the keyboard and contains the circuitry, resistors, and diodes that convert keypresses into electrical signals and send them to a computer. Typically comprised of glass fiber with copper traces, some PCBs also have light-emitting diodes for RGB lighting. These RGB lights shine through transparent RGB switches, and then through shine-through keycaps. PCBs can include components such as a USB port to charge a device or transfer files, or a volume wheel or knob. Wireless PCBs may also contain a dongle port to transmit keystrokes wirelessly.

In most cases, switches are soldered to PCBs. That’s true for plate-mounted switches; even though they’re mounted to plates, they’re still soldered to PCBs. The plates offer additional stabilization. Some PCBs are hot-swappable, which means switches can be swapped in and out without soldering. Hot-swappable PCBs are convenient, though they can be less stable than soldered PCBs.

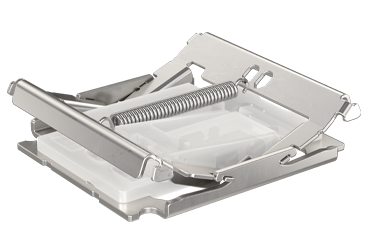

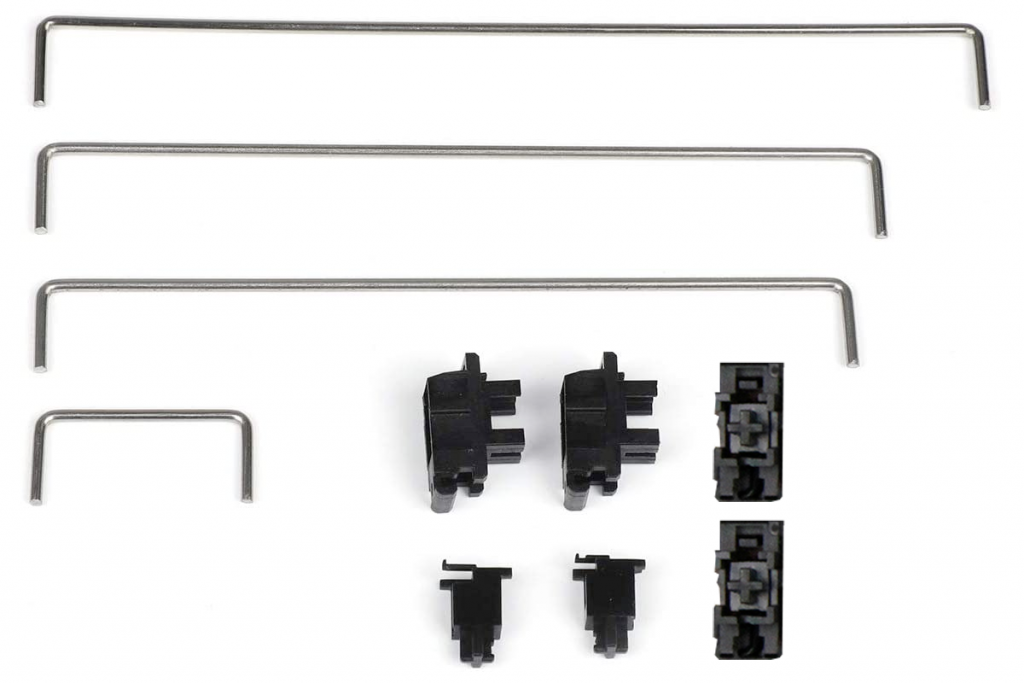

Keyboard Stabilizers

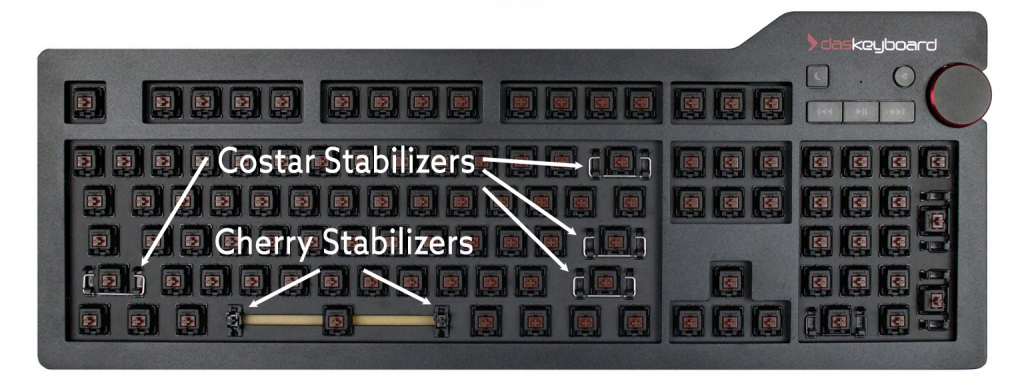

Stabilizers (also known as stabs), remove any wobble when typing and ensure a consistent keypress for the larger keys such as enter, shift, backspace, caps lock, and the spacebar. They work by spanning the undercarriage of each keycap so that the switch, which is located in the middle of the keycap, doesn’t tilt to one side and reliably activates the switch no matter where the key is pressed.

Press the right side of a spacebar without a stabilizer, and it will tilt to the right, potentially failing to activate the switch. With a stabilizer, the entire key depresses and activates the switch. Stabilizers also help prevent keys from wobbling and rattling. The two most popular types of stabilizers are Costar stabilizers that have a bar that hooks into stabilizer inserts inside the keycap, and Cherry stabilizers that look just like the stem of a Cherry MX switch (also pictured above).

There are three styles of keyboard stabilizers:

- Plate-Mounted: Clip onto the plate

- Screw-In: Screwed directly to the PCB

- Snap-In: Snap directly to the PCB

Screw-in stabilizers are considered the best because they offer the most secure stabilization. Keyboard enthusiasts that build their own keyboards will often modify their stabilizers for additional support and even less rattle by trimming two of the tabs on the bottom of the stabilizer and then cutting a small piece of bandaid to stick to the PCB before installing the stabilizers. This is known as a bandaid mod in mechanical keyboard communities.

Even though a keyboard seems like a simple device, there are many parts of a keyboard that work together to convert keystrokes into electrical signals, then send them to a computer. Each part of the keyboard plays an important role, and the quality of each part can significantly impact performance. Serious gamers, writers, programmers, and business professionals recognize how important keyboards are to achieving their goals or improving their productivity and emotional attachment to their work. This is why they choose a mechanical keyboard with the best quality parts that will help enhance their typing speed, accuracy, comfort, and enjoyment while keyboarding.